The Opportunity

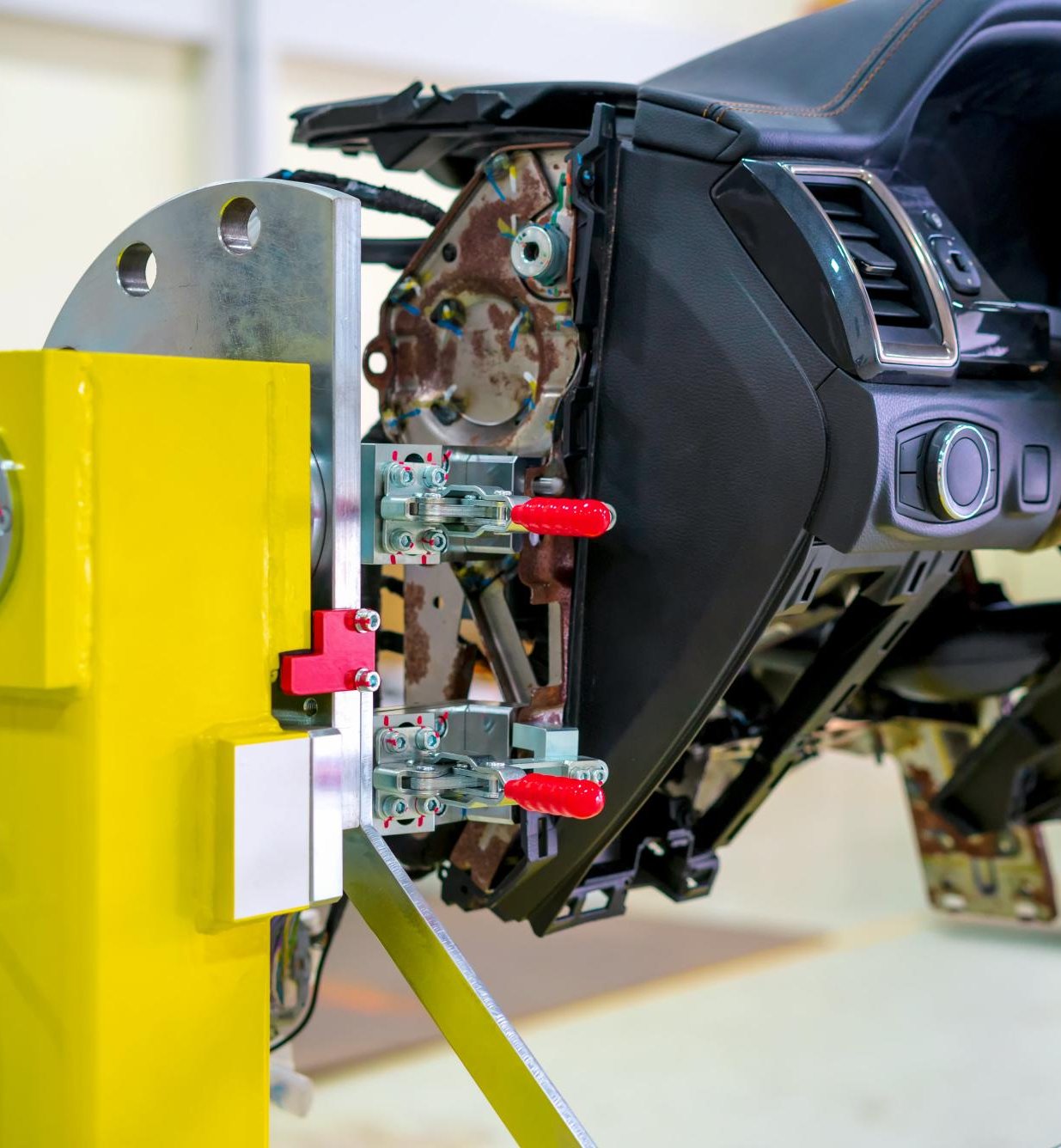

Our automotive IP / consoles customer has a very wide range of small assemblies, that together form full instrument panels and consoles for an automotive OEM.

A critical part of the assembly process is a 'No Faults Forward' methodology. When a single missing part can cause customer plant rejections - it is imperative that each assembly is right first time!

The huge variety of designs within the vehicle generates a massive amount of potential for failure of the process so it is essential that they are stopped at source and prevented from escaping the assembly process.

The Solution

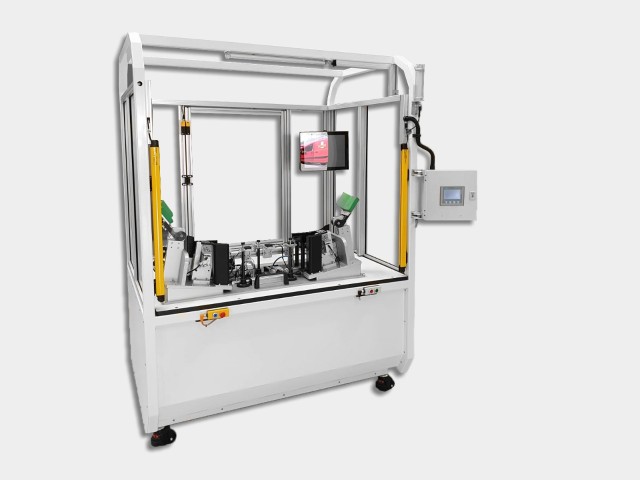

Using a standard bench format, in a range of sizes, we design and manufacture NFF sub assembly systems equipped with Torque driver(s), process control HMI assemblies, bar code scanners, sensor IO, bar code printers and a variety of materials and techniques to engineer a process that cannot allow a faulty part to escape.

Part sensing, clamp engaged sensing, DC tooling feedback is used to control the assembly process at each step - with the process moving forward only upon receipt of an appropriate sensor confirmation, synchronised with operator instructions via the assembly process.

The examples below use a Desoutter Infinity HMI for process control and monitoring of IO via ethernet from the remote panel, which is fully integrated into the customer plant for traceability. The result is a fully Poka-Yoke'd assembly process, to survive the rigours of 24/7 use.

The Benefits

- Lower operating costs

- Improved worker safety

- Reduced factory lead times

- Ability to be more competitive

- Increased production output

- Consistent and improved part production and quality

- Optimal utilization of floor space

- Easy integration

- Maximized labour

- 24/7 non stop production with minimal maintenance

With more than 160 years of automotive interiors expertise, International Automotive Components (IAC) is a leading global supplier of automotive components and systems. We bring added value, service, and success to our customers, investors, and employees, reinforcing our quality, value, and technology.

No fault forward

Traceability systems

Poka-Yoke assemblies