The Opportunity

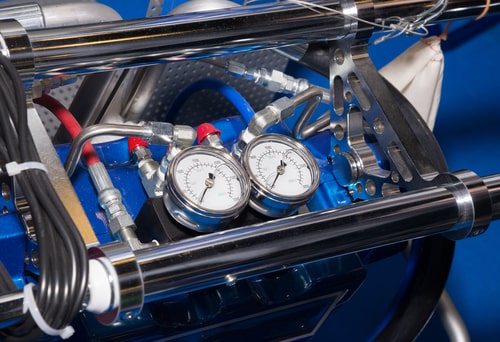

Working directly with the site management, we were selected to supply and install new energy efficient machinery to replace the 10 year old equivalent units.

The Solution

The new equipment selected was a full 35Kw smaller in size and was 60% smaller in regard to footprint. Embedded within this machine, are facilities to provide instantaneous alerts to the client should the new machinery require servicing or incur any issues.

- Energy audit to ascertain correctly sized equipment

- Gannt chart to allow installation to be carried out around customer workload

- Isolation and removal of current compressors

- Modification and testing of pipework to allow installation of new compressors

- Electrical and mechanical installation

The Benefits

- New ducting to recover heat energy for secondary use

- Full integration of controllers to allow most efficient running operation

A world leader in the supply of foundry consumables and solutions.

60%

Reduction in carbon footprint

Four

Week turnaround

£44k

Project